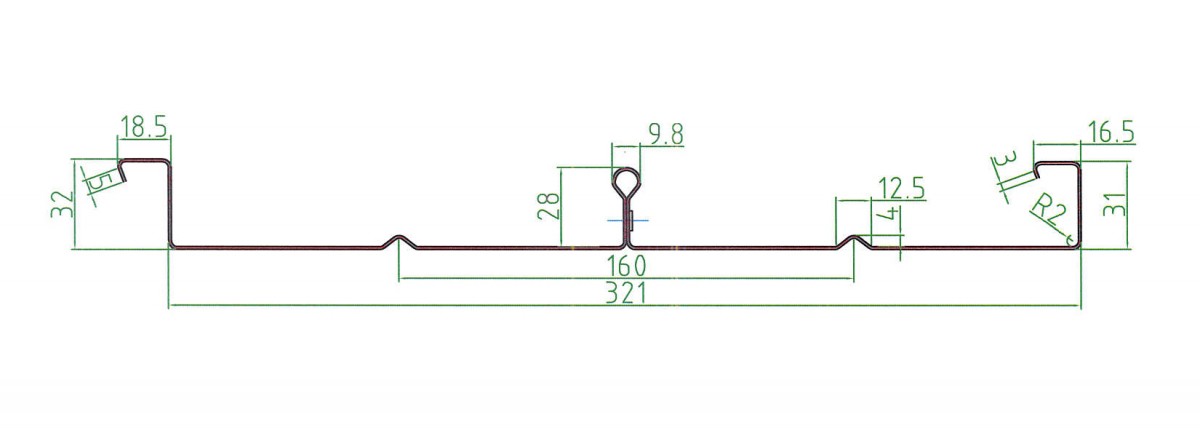

LOK-RIB30 Composite Decking Profile

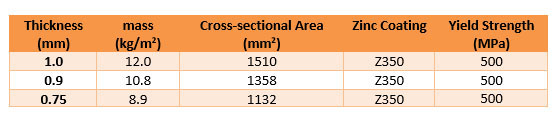

Formdeck LOK-Rib30 decking is supplied in three base metal thicknesses of 0.75mm, 0.90mm and 1.0mm.

Experimental testing and Analysis on the RIB30 profile has been carried out in accordance with AS4600 – Cold Form Steel Structures and AS/NZS2327-2017 Composite structures – Composite steel-concrete construction in buildings to determine the characteristic properties of the profile for the design and use of the RIB30 as composite decking.

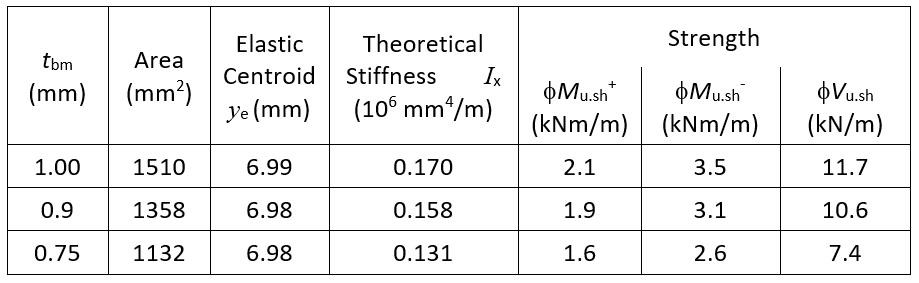

LOK-Rib30 Profile (per metre Width)

LOK-RIB30 Design

The design of suspended slabs using the LOK-Rib30 profile requires consideration of the profile decking under the following conditions:

Formwork Stage – during construction of the composite slab and considers placement of decking and associated reinforcement, concrete pouring and other loading associated with construction.

Design for the formwork stage is dependent on the applied loads and deflection limits in accordance as per AS/NZS 1170.1 and AS3610. Design may be carried out using engineering principles along with the characteristic properties outlined on the properties page or by using the LOK-Rib30 Formwork Tables.

Composite Slab – after the concrete has reached it design strength and the profile acts with the concrete and other reinforcement to provide the required strength for loads arising throughout the life of the structure.

Design for the composite slab is carried out in accordance with AS/NZS2327-2017 based on the defined loading, the deflection requirements, the environmental conditions and other design life considerations. The slab spanning capacities may be determined using the capacity tables for various slab thicknesses and varying degree of shear connection by using the LOK-Rib30 Composite Tables.

LOK-RIB30 Design Properties

The characteristic Design properties used for both the formwork stage and composite design for the LOK-Rib30 Profile are:

LOK-RIB30 PROFILE PROPERTIES (PER METRE WIDTH)

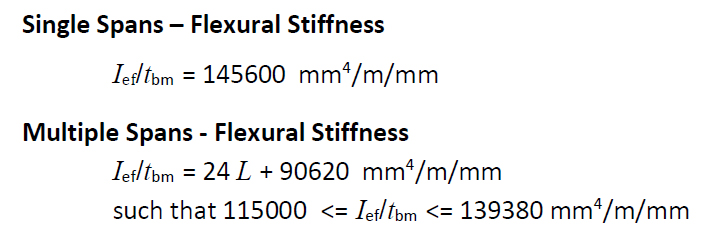

Flexural Stiffness – Formwork Stage

The Flexural Stiffness for the sheeting has been derived from testing of the deck profile under both single and multiple span configurations with varying spans and thicknesses. The modulus of elasticity (E) of the steel sheeting is assumed to be 200,000MPa and yield strength (fy) of the sheeting is assumed to be 550MPa.

The stiffness of the profile is affected by the length of the span and the number of spans. For the development of the spanning tables the stiffness is defined by the following equations for both the single and multiple spans.

In both cases L is the free span of the of the decking and the thickness of the base metal (tbm) and measured in millimetres.

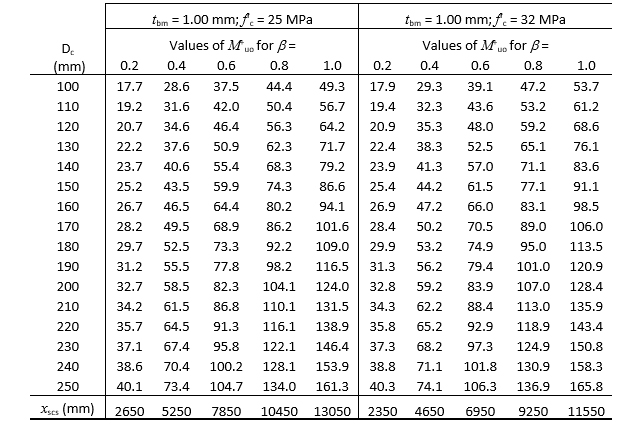

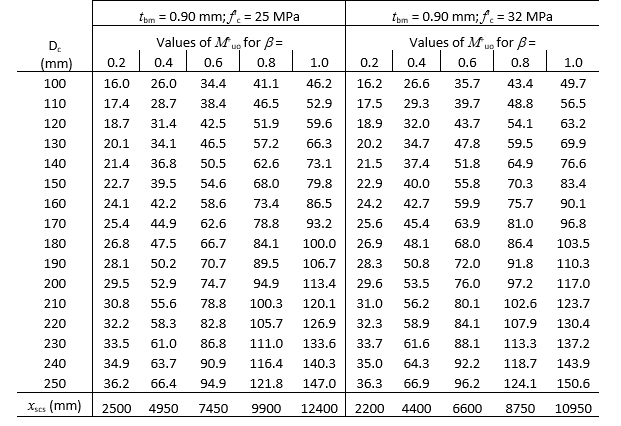

Composite Strength

The composite strength of the slabs of varying thickness are calculated in accordance with AS/NZS2327-2017 Composite structures – Composite steel-concrete construction in buildings -Section 2 are tabulated below. The degree of shear connection (![]() ) is determined by the distance from an end point of the deck that is free to slip to the point being considered. Full shear connection (

) is determined by the distance from an end point of the deck that is free to slip to the point being considered. Full shear connection (![]() = 1) occurs when the profile decking has sufficient length (xscs) to develop full stress in the decking profile.

= 1) occurs when the profile decking has sufficient length (xscs) to develop full stress in the decking profile.

LOK-Rib30 Composite Capacities M+uo – tbm = 1.00 mm (per metre width to AS/NZS 2327)

LOK-Rib30 Composite Capacities M+uo – tbm = 0.90 mm (per metre width to AS/NZS 2327)

LOK-Rib30 Composite Capacities M+uo – tbm = 0.75 mm (per metre width to AS/NZS 2327)

LOK-RIB30 Formwork Tables

The formwork tables are generated utilising the flexural stiffness and strength as detailed under design properties.

The spanning tables have an allowance for concrete ponding and other loading in accordance with Australian Standards AS1170, AS3610 and AS2327 including the 4 kPa live load allowance for stacking materials.

Concentrated loading should be avoided at the sheet overlap joints and unsupported edges, and mounding of concrete above finished concrete levels should be avoided.

The following assumptions are made:-

- Concrete density assumed to be 2400Kg/m3

- multiple spans are poured simultaneously to ensure deflection limits are maintained.

- Mounding of concrete during pour does not occur.

- support widths are 50 mm at profile ends and 100 mm over intermediate supports.

- multiple spans do not vary by more than 5% and that maximum spans are not exceeded.

Supporting structure and propping should be designed and verified as suitable for all loads cases by a registered engineer.

The theoretical deflections are based on the above assumptions and may vary depending on the density of the concrete, the weight of reinforcement or the sequence of the concrete pour.

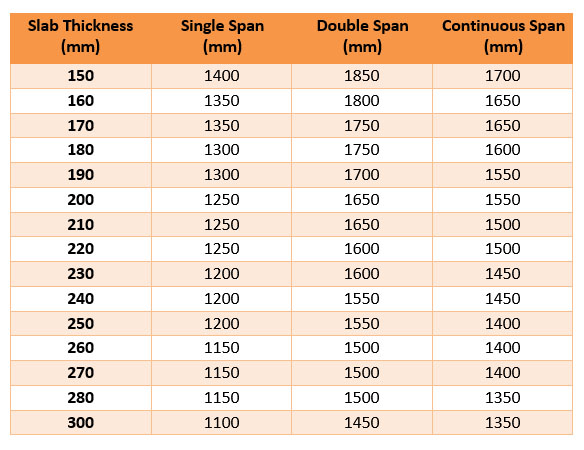

LOK-RIB30 – 1.0 mm Base Metal Thickness – Deflection Limitation L/150

LOK-RIB30 – 1.0 mm Base Metal Thickness – Deflection Limitation L/240

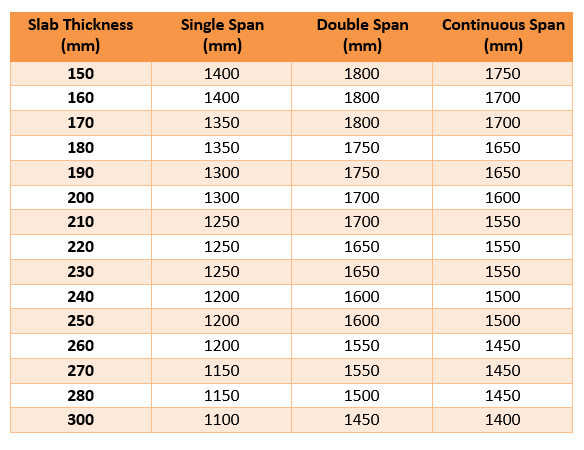

LOK-RIB30 – 0.9 mm Base Metal Thickness – Deflection Limitation L/150

LOK-RIB30 – 0.9 mm Base Metal Thickness – Deflection Limitation L/240

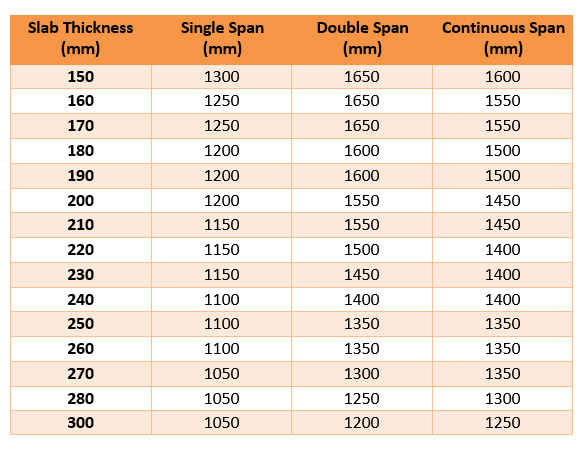

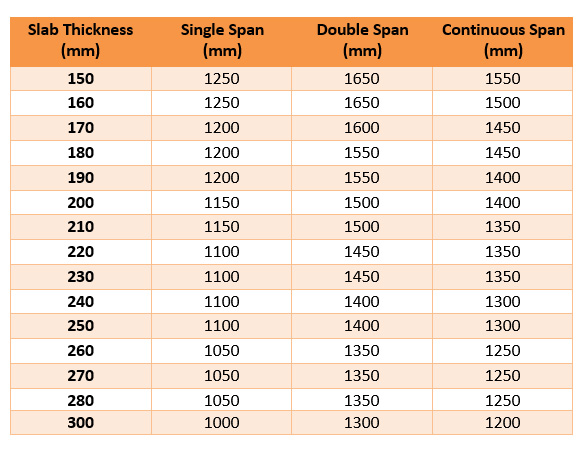

LOK-RIB30 – 0.75 mm Base Metal Thickness – Deflection Limitation L/150

LOK-RIB30 – 0.75 mm Base Metal Thickness – Deflection Limitation L/240

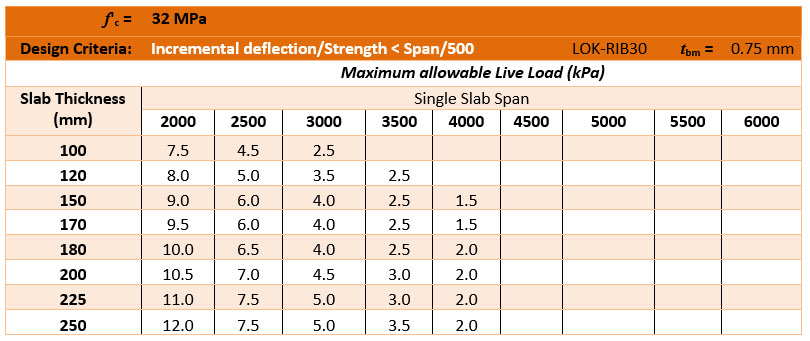

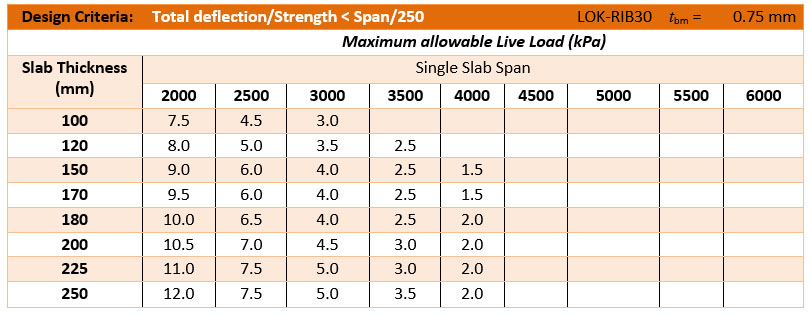

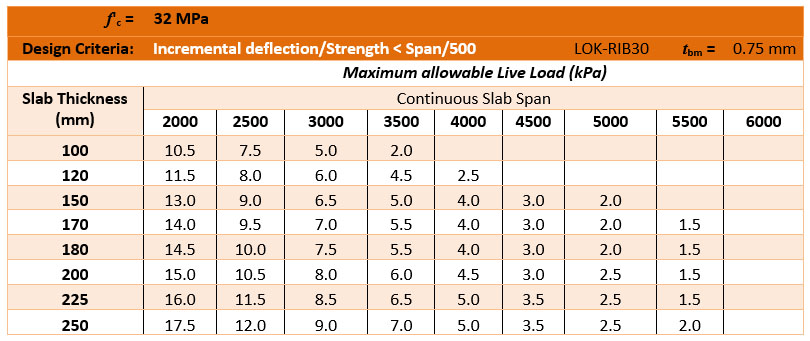

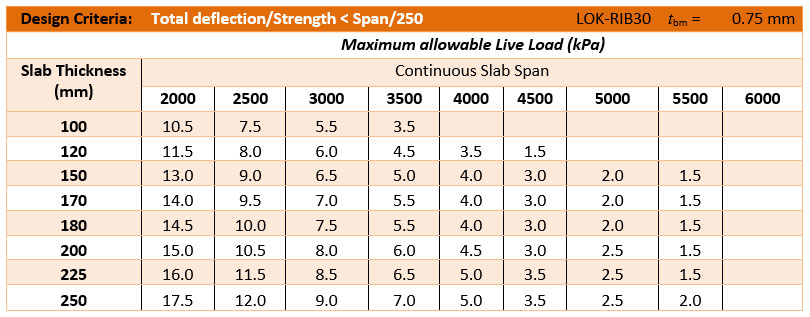

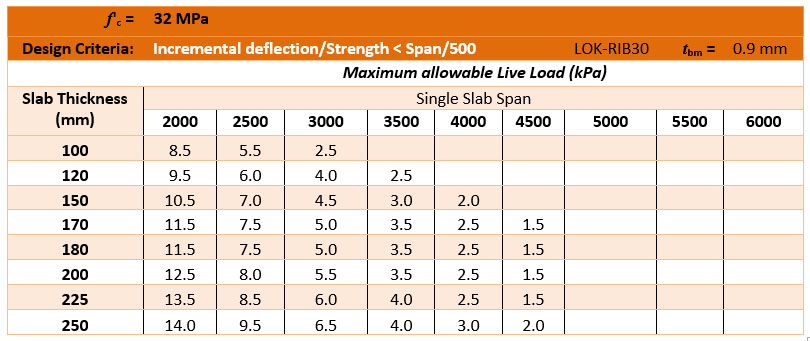

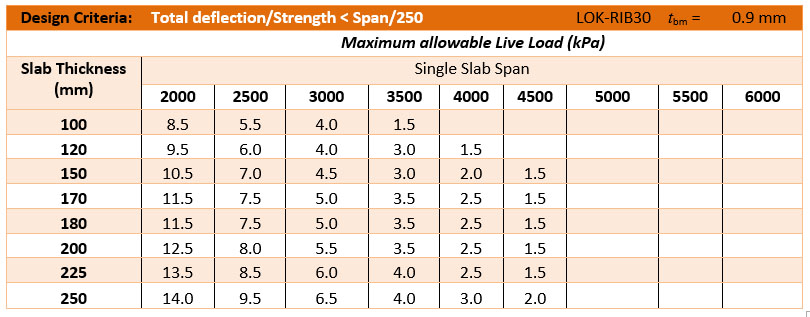

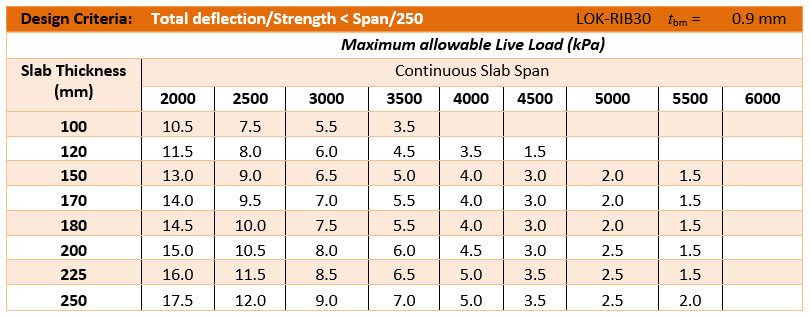

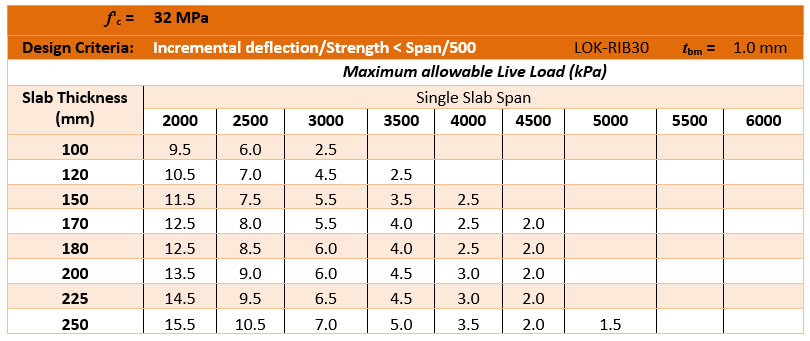

LOK-RIB30 Design Loads

The design loads for both strength and serviceability are based on the load combinations as defined in AS1170.0-2002. The design tables have been developed utilising ‘Limit State’ principles as detailed in AS/NZS 3600-2018 – Concrete Structures Standards, AS 2327-2017 – Composite Structures Standard and AS1170 – Structural Design Actions.

The design spans and slab thicknesses are defined and the allowable imposed actions (Q) for each combination is presented. The Slab thickness and the type of Span (i.e. single or continuous) are detailed for each table. The self-weight and superimposed dead loads (0.5 kPa) are defined in accordance with AS1170 and AS2327.

The table presents the span from centre to centre, and the allowable imposed loads in the positive bending region of the span for the various base metal thicknesses. The negative reinforcement is assumed to be detailed by the design engineer with no allowance for moment redistribution.

The following assumptions are made in the presented tables

- The type of construction is steel frame construction or equivalent

- There is a minimum support width of 100 mm at the permanent supports

- Multiple spans have equal spans, with the span measures from centre to centre of supports

- Concrete strength f’c = 32 MPa

- Concrete density is 2450 kg/m3

- Classification is A1 exposure, with 20mm cover to reinforcement

- Slab deflection limits for L/250 for total loads and L/500 for incremental deflections are imposed

- Superimposed Dead load is 0.5 kPa

- Minimum degree of crack control for shrinkage as per AS3600 is utilised

- Internal spans may be increased by 15%

- For multiple spans negative reinforcement to be as detailed by design engineer

- The appropriateness of the utilisation of the tables has been carried out by a registered structural engineer with consideration for long-term deflections and capacities considered.

- Back propping to engineering specification

Minimum shrinkage reinforcement for LOK-RIB30 slabs

(minimal crack control longitudinally)

LOK-RIB30 Composite Tables – tbm = 0.75 mm – Single Span

LOK-RIB30 Composite Tables – tbm = 0.75 mm – Continuous Span

LOK-RIB30 Composite Tables – tbm = 0.9 mm – Single Span

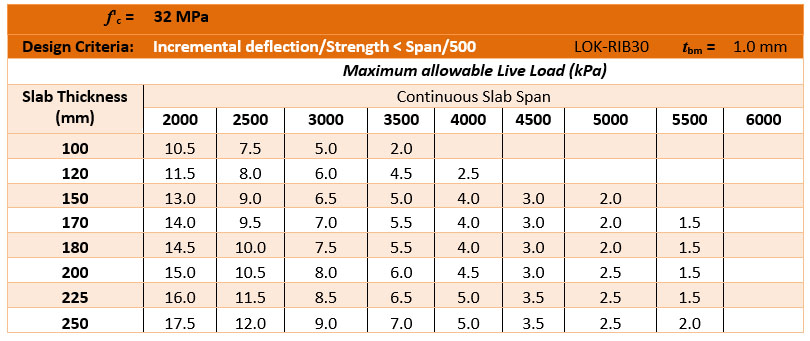

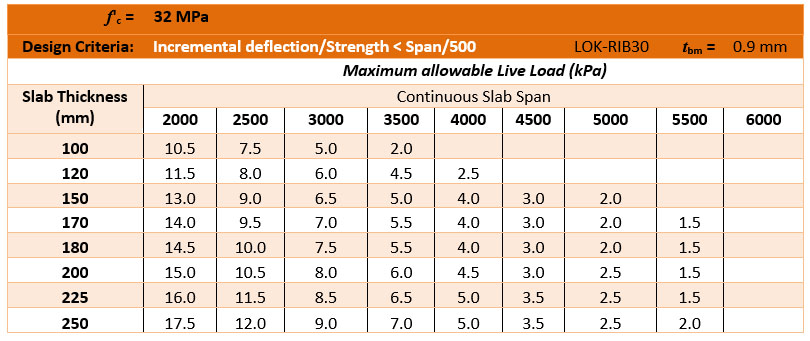

LOK-RIB30 Composite Tables – tbm = 0.9 mm – Continuous Span

LOK-RIB30 Composite Tables – tbm = 1.0 mm – Single Span

LOK-RIB30 Composite Tables – tbm = 1.0 mm – Continuous Span